Remote Controlled Tracked Slasher

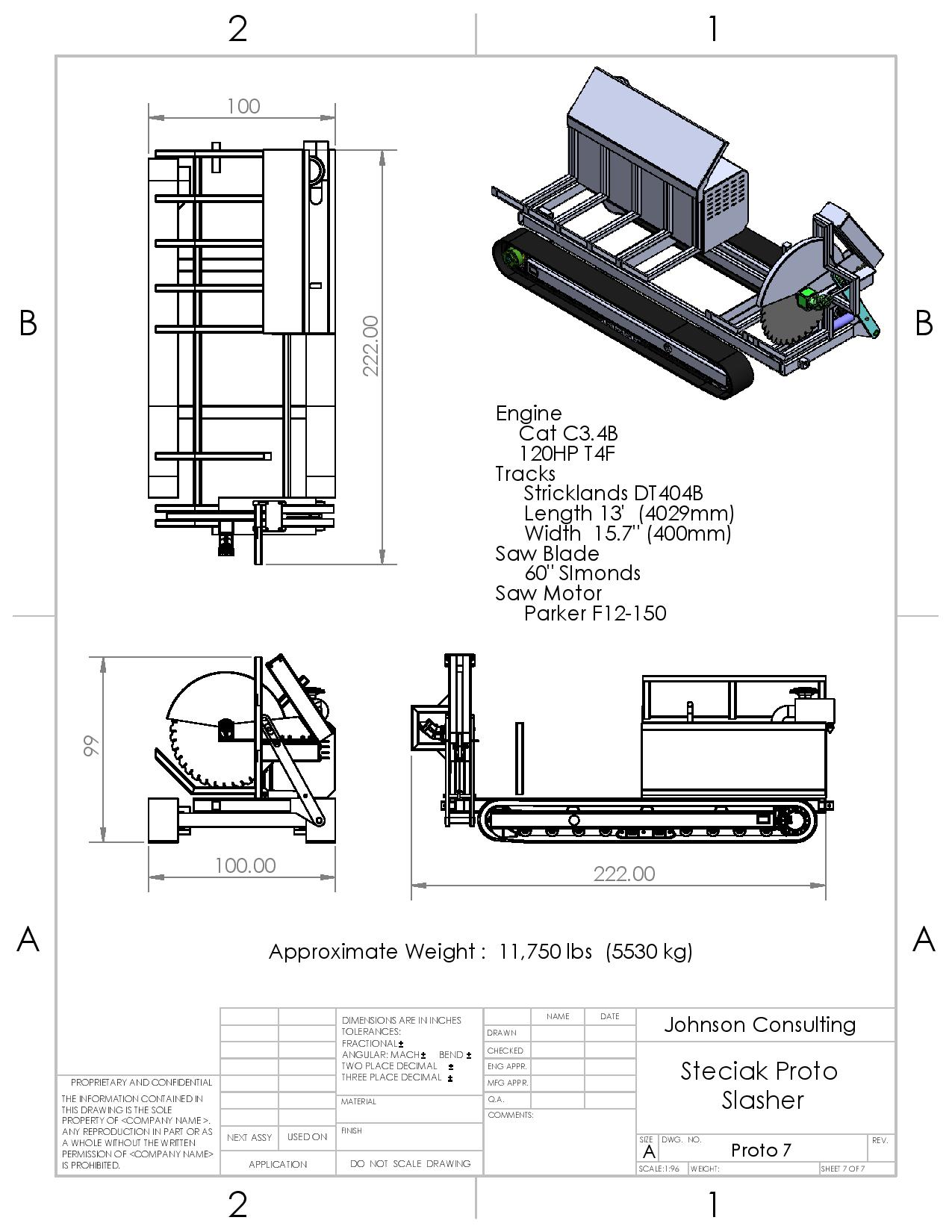

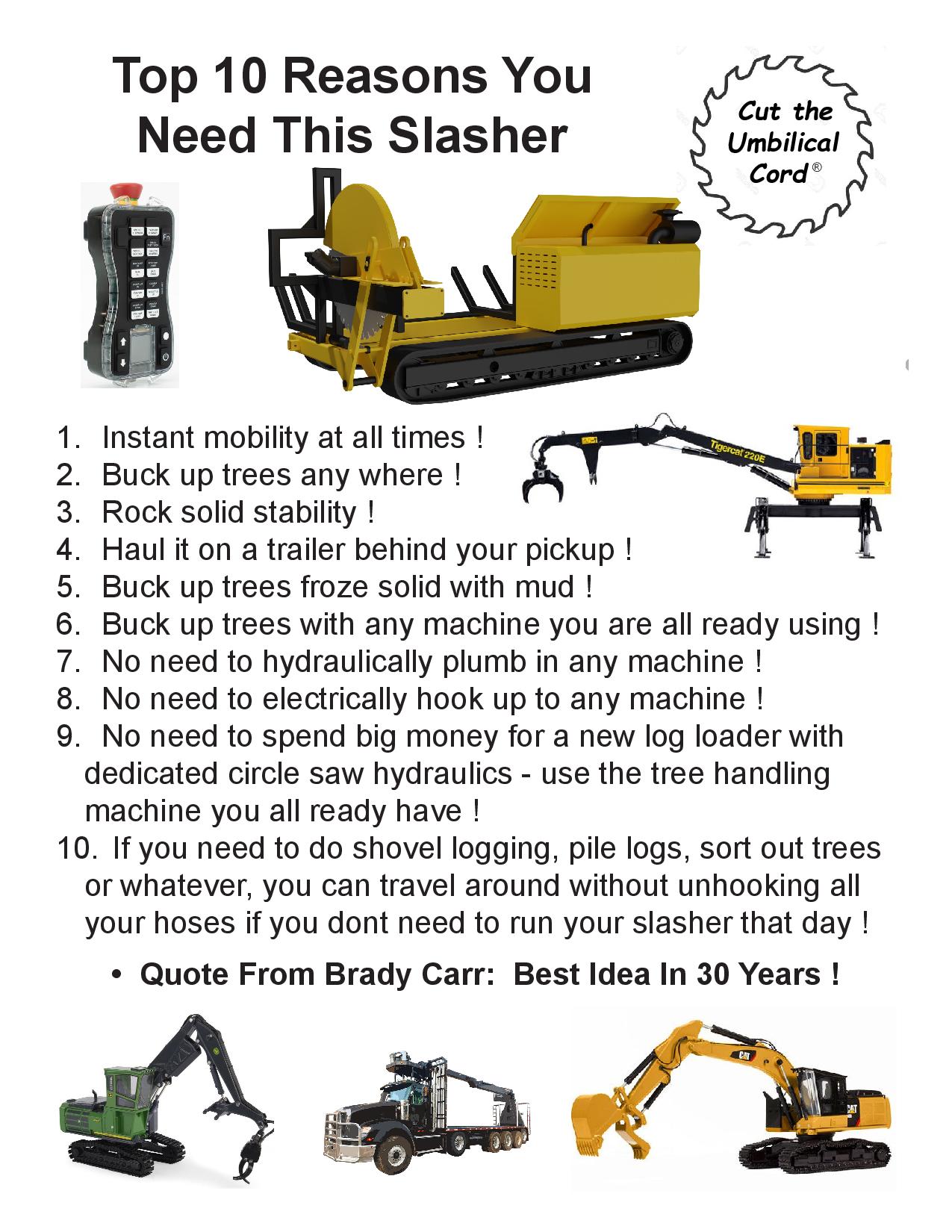

“Cut The Umbilical Cord”® with a self-powered slasher mounted on a self-propelled track carrier similar to tracked chippers and grinders. The low and long undercarriage keeps the slasher close to the ground and stable. It can be turned and adjusted at a moment’s notice to fit the ever changing scene on a modern logging job. All with no hydraulics or electrics to hook up. The radio remote control can be used in any log handling machine.

Browse more images below…

Could This Loggers Invention Change the Logging Industry?

By Eileen Townsend

Plenty of loggers encounter hurdles working in the woods. How many guys on the job have said, at one point or another. “If only this thing would work like this....” When you work in the woods, frustration can be a part of the job. But what sets successful loggers apart from the unsuccessful is what they do with that frustration. You can either throw up your hands and quit, or, if you’re like John Steciak Jr. you can see a problem as your prompt to innovate.

John Steciak Jr is a second-generation logger based in Dolgeville, New York. Like many loggers, he does a little bit of everything to keep himself busy and business strong: bulldozing, excavating, road building, timber harvesting. A few years ago, Steciak had the thought to update his excavator. He also wanted to replace his truck-mounted loader and circular saw with a more versatile crawler log loader. But he balked at the price of the equipment... sold new, the excavator he wanted cost between $250,000 and $300,000 and the crawler loader was $350, 000 to $400,000 Said Steciak, “How does a small operator like myself justify a return on investment like that? Especially when you don’t want to live beyond your means and be a slave to the lender for years? How can anyone in this economy afford both a new crawler log loader and a new excavator?”

Then John’s thoughts started to get creative. Said Steciak, “I thought, a log loader’s boom geometry is great for lifting but not so good job at logging. But you can’t cut up timber with it.” That's when it hit him: “How about a self-contained, cordless, remote-controlled circular saw on tracks?” As soon as he’d had the idea, he decided he’d have to build a prototype. Steciak set to work in 2017 to build his tracked slasher. “ I thought, on a regular logging job, you’re hooked up to this thing all the while and it’s quite a job to unhook the hoses and then you lose a little oil sometimes. It’s also dirty and messy. But having a separate machine ...it makes life much easier. You can stop what you’re doing and go load a truck and pile some logs and you don’t have to unhook from the slasher.”

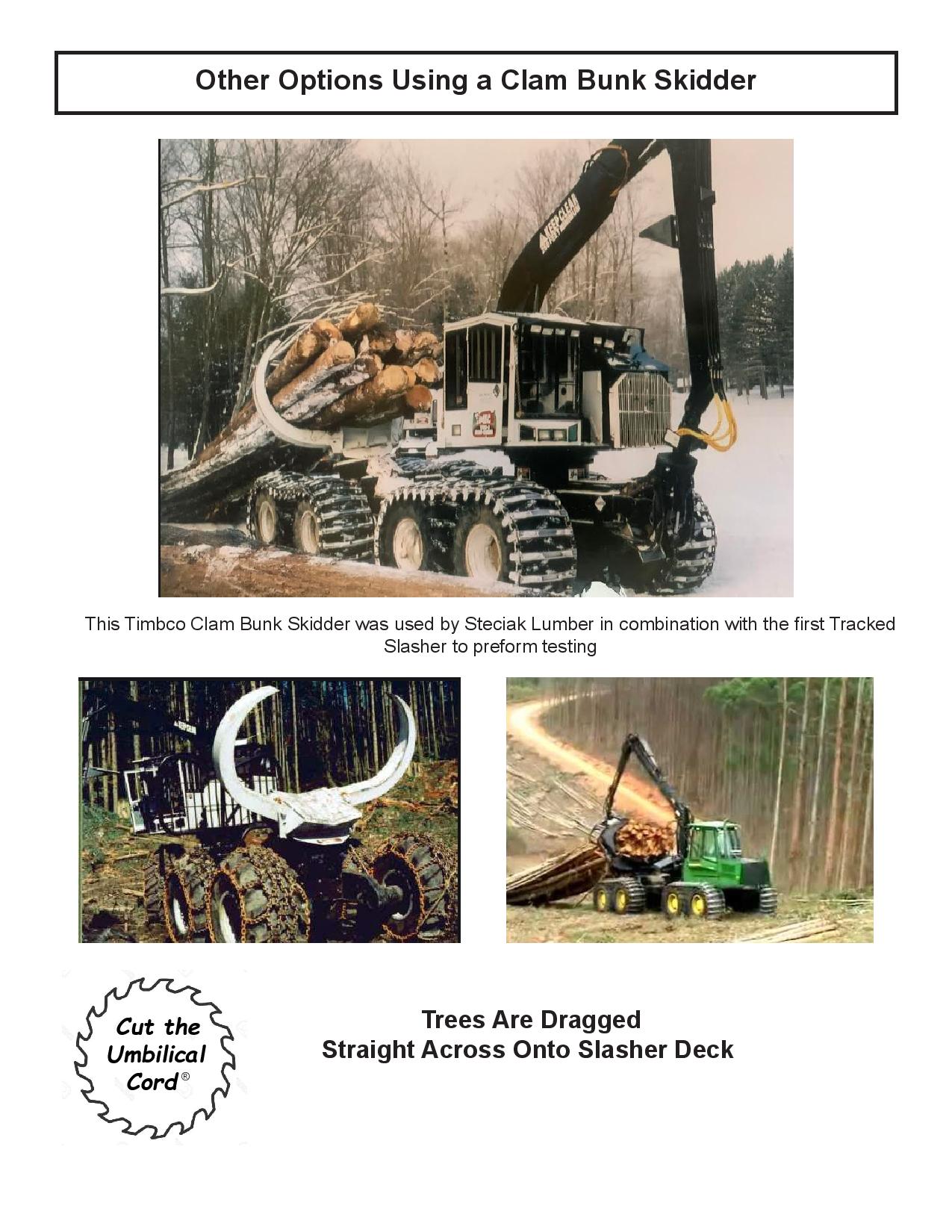

He then purchased a 336 Cat Excavator with a compete forestry package, 72”-inch rock bucket, and Rotobec grapple. Then he got to work in the woods, testing his new method. His creativity paid off. “After successful trials, “ said Steciak, I could see that my idea worked. “ His father, retired logger who is pushing 100 years old, told his son that he needs to get his invention patented, So Steciak did, 3 of them, Canada too! “Cut the umbilical cord” which describes the slasher to a tee is a registered trade mark.

Steciak also got in touch with a consultant who he hoped would help him market and refine his idea, engineer named Tom Johnson who’d worked for Morbark, Bandit and Terex, side John. “Together, Tom and I have developed a machine that I think will benefit loggers large and small. Johnson, for his part, at first hesitated to take on a collaboration because he was worried that someone had invented a tracked slasher already the idea seemed obvious, surely it had to exist, thought Johnson. But after several weeks of research he confirmed that Steciak’s idea was an innovation. “I can see all the advantages” said Johnson. It’s remote controlled and its on tracks, so it can go anywhere you want it to go. Setting up a site is always difficult, trying to get all the equipment in the right spot. A normal slasher can’t move on it’s own, so you always have to have equipment come up and move it, even if you just want to move it three feet. With this one, the operator is sitting in his cab and he has a remote control, so he can move it in position and out of position. It’s all self contained. It has its own engine and its own hydraulic system. It’s less susceptible to oil contamination from the loader, which most slasher’s aren’t” Also adding in an advantage when working down south in high heat areas there will not be the overheating problems with a separate hydraulic system.

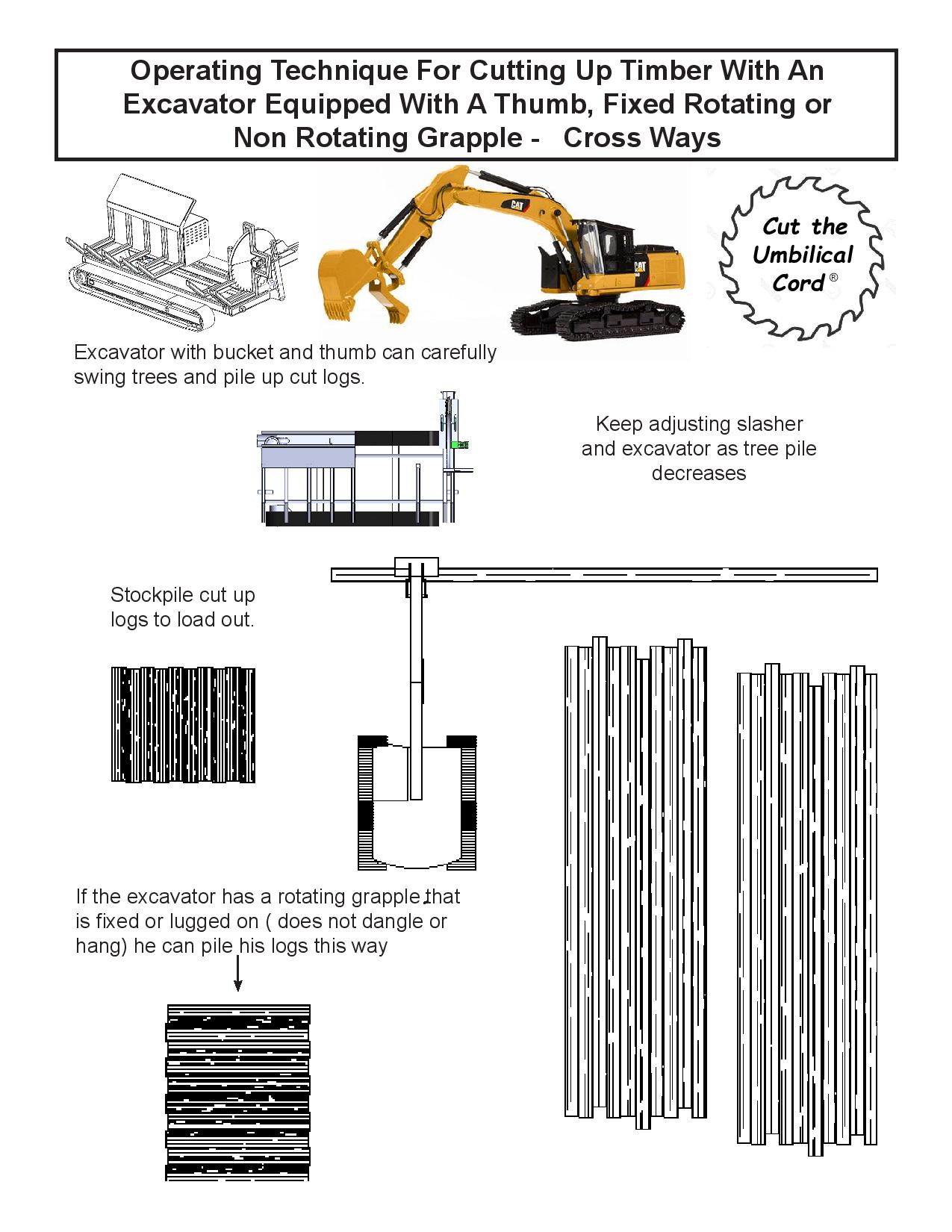

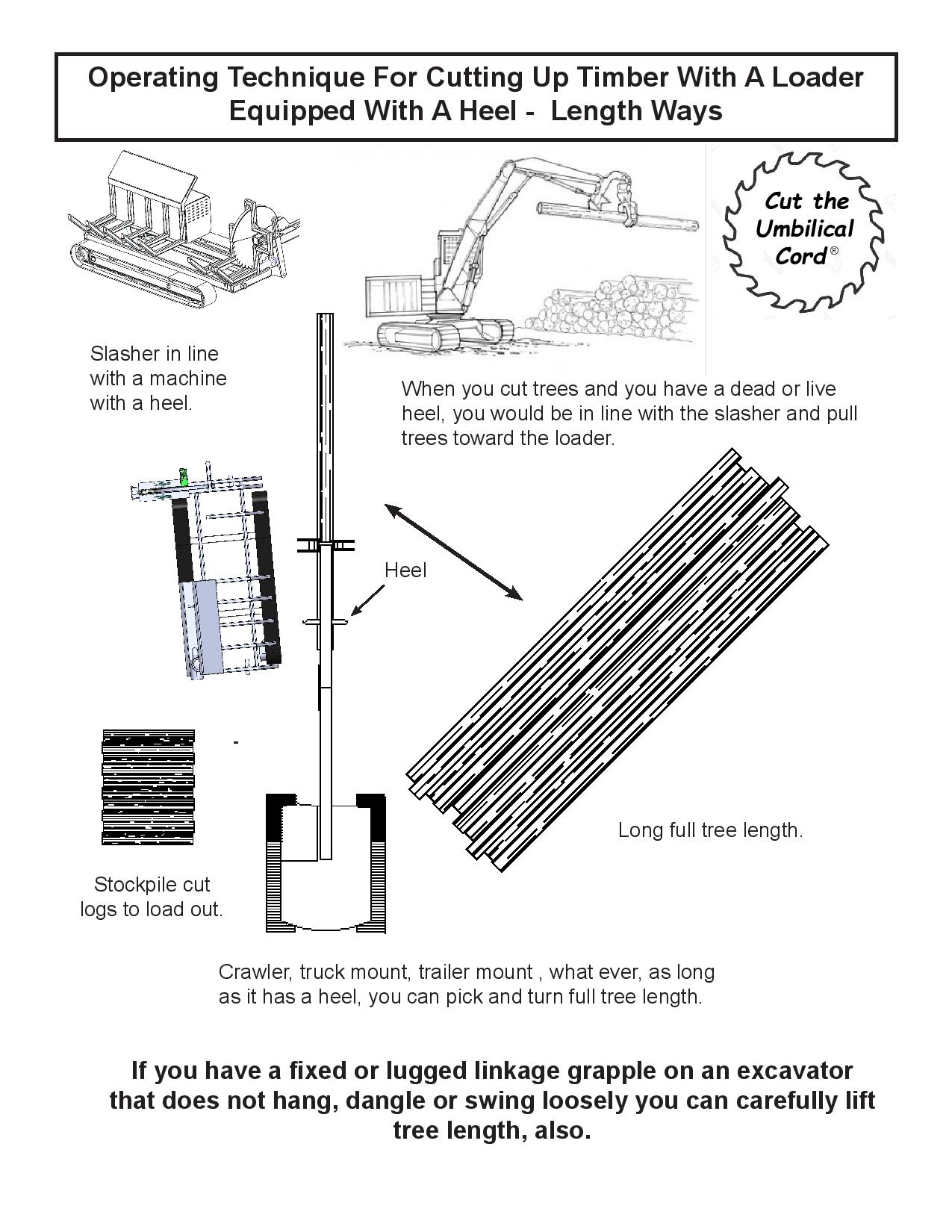

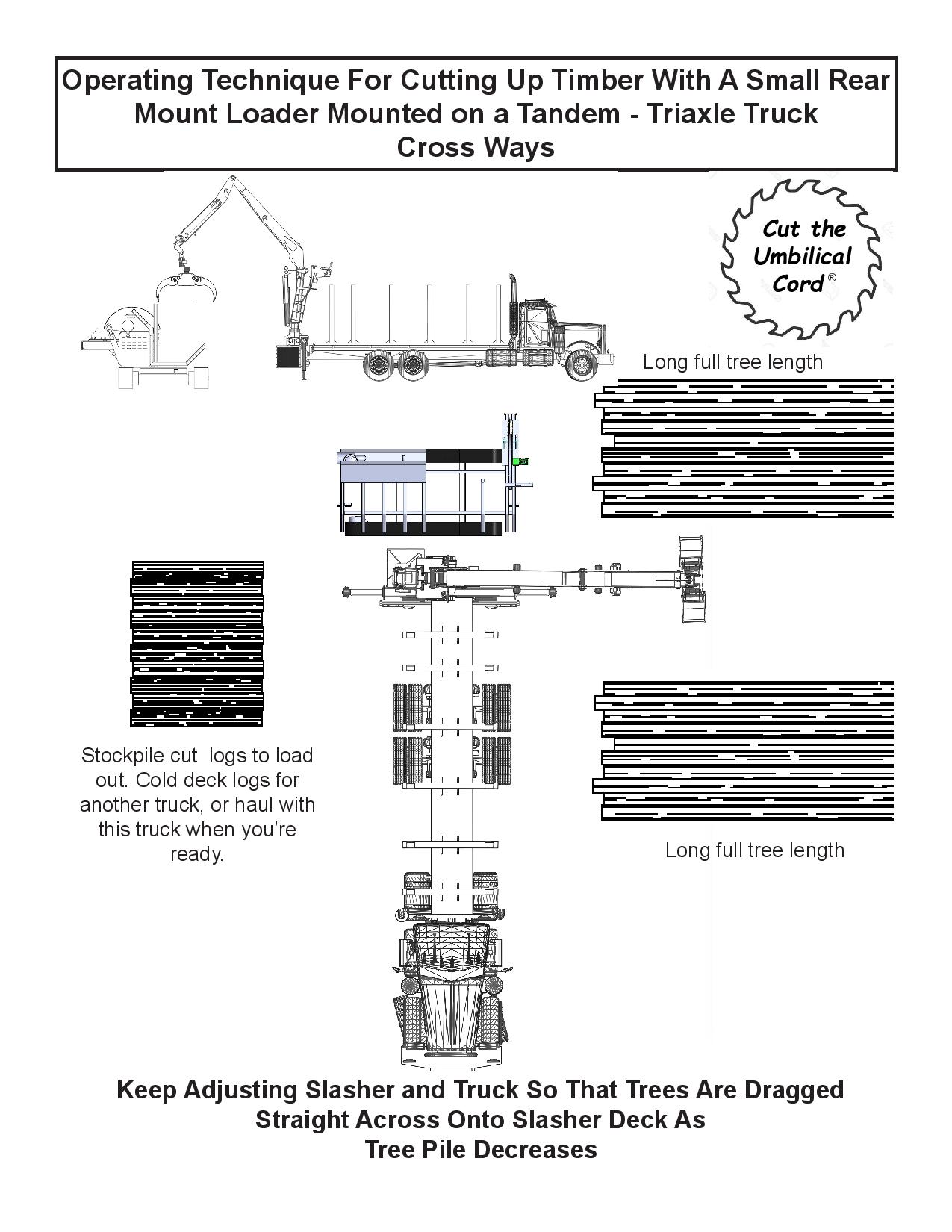

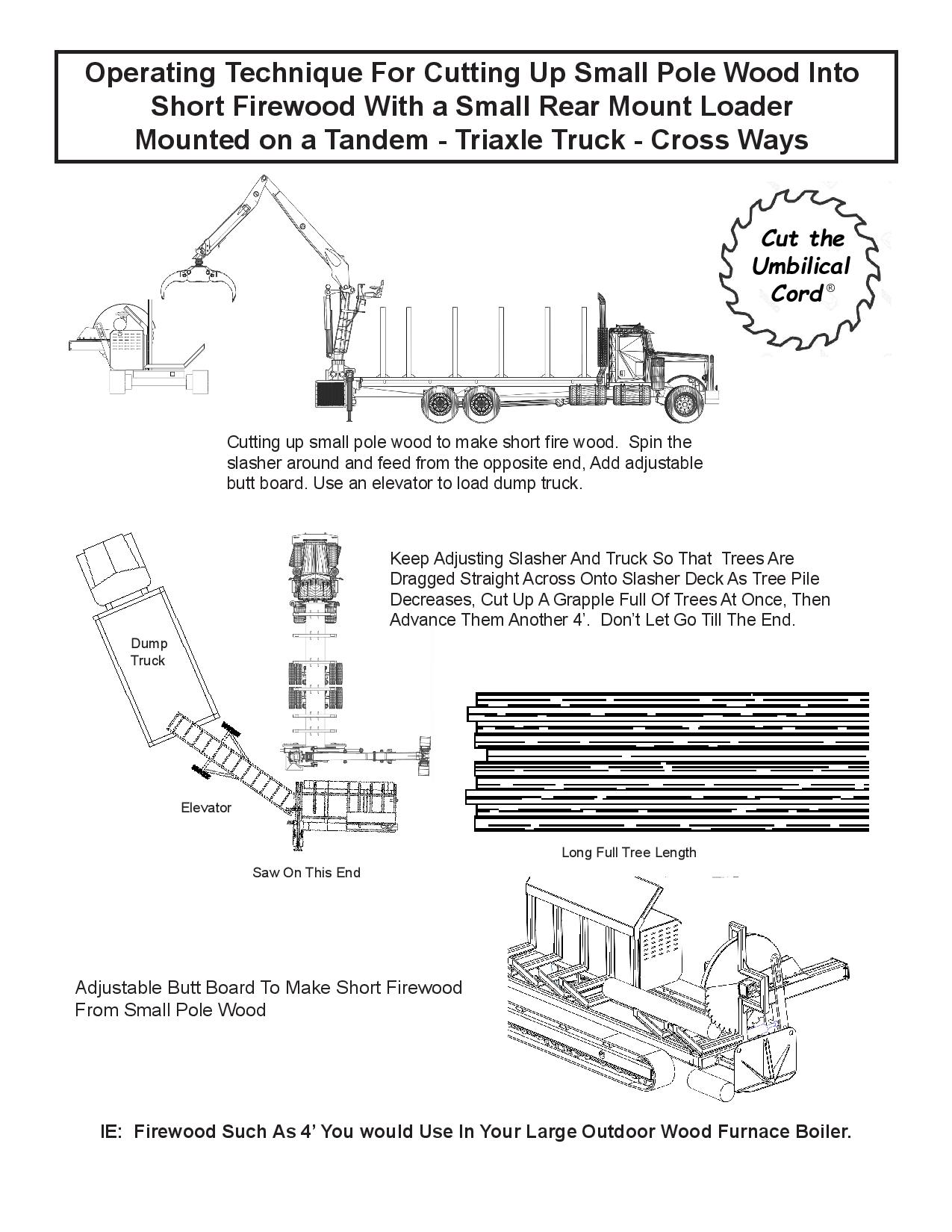

For the first time ever now an excavator with a hydraulic thumb can carefully cut timber, furthermore a rear mounted loader on a tri axle truck can drag trees on to the slasher to buck up wood crossways. Said Johnson, “This is looking way outside the box. They’ve been building slashers for so many years and no one has ever built one like this that I could find. Its innovation out of necessity.” Johnson helped Steciak refine has prototype and draft a new model of the tracked slasher. Currently, Johnson and Steciak are in what they call the “market research” phase of the project. They’re hoping to find a manufacturer who will put the tracked slasher into production, so that other loggers can have access to this easier ways of bucking up trees. “I think part of its is just finding the right company.” said Johnson - We’re looking for a company that already has dealerships and is connected to the logging business. We’re looking for a company that understands hydraulics, remotes and tracks and can help put this together.

For now, Steciak and Johnson are getting the ball rolling. Despite the hurdles presented by Covid-19 and the fact that they are working remotely (Tom is based in central Michigan, the chipper capital of the world”), they’re anxious to see this modern innovation in the woods. “I think this is super cool,” said Johnson. “I can’t believe it’s not out there yet. It’s definitely unique.”